Paragon Rag Joint Repair Kit

Collapse

X

-

Re: Paragon Rag Joint Repair Kit

Hi John here are a couple of more shots. Jim- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

This may be a bit off topic but it does provide some insite as to our current problems.

Back 43 years ago, I was a product engineering design group supervisor. I was responsible for flexible steering shaft couplings and power steering pressure hoses for the C2/C3 Corvette and all the other GM vehicles in the 70s and early 80s. So I do have quite a bit of experience with these products.

In those days, virtually 100% of the General Motors passenger cars had a rigid frame and a seperate body mounted to that frame with rubber body mounts. Those General Motors vehicles also utilized a rubber element between the steering column (part of the body) to the steering gear (part of the rigid frame.) There were five basic reasons why there was a flexible disc (with 4 or 7 laminations of neoprene rubber and cotton cloth) in the shape of a flexible steering shaft coupling assembly. The functions of that part were as follows:

1). Absorb rough road shocks from reaching the steering wheel.

2). Isolate road and hydraulic noise from being transmitted into the driver compartment.

3). Allow for body to frame tolerance and minor movement between the body and frame as the vehicle is being driven.

4). Accommodate any design angle between the steering column and the steering gear.

5). Provide a reliable ground path for the horn.

I think that there are universal joints that have a rubber damper element as part of the design. This would allow the part to accomplish the function of #1 , #2, and #4 above. I don't know about #5.

However, a universal joint is very rigid therefore it wll not allow for any misalignment of the steering column to the steering gear. Also a universal joint will not allow for body to frame movement.

Our fear, as the design responsible steering Division, was that the lower column bearing and the lower steering column jacket would not be able to absorb any movement of the body to the frame during the life of a car. Therefore a rubber element between the two was required.

Now I am fully aware that there are many aftermarket steering systems for the C2/C3 Corvettes that now incorporate a universal joint. Also I am fully aware that quality flexible coupling assemblies are becoming quite rare.

So the best that I can do is try to council people making installations with rigid univeral joints is to keep a close eye on the installation and be alert to any looseness or degradation of the lower steering column bearing.

Jim- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Jim,

Looking at your pictures in post #17, I believe the rag joint should be turned 180*. The riveted rag and flange go on the steering column shaft while the other flange comes on the steering box.

Sorry Jim, my bad, I haven't had enough coffee today.:-)- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Tim -

The photos in post #17 show the correct installation - the entire rag joint/coupler assembly came as part of the steering gear, with the nuts facing the steering gear and the safety pins facing the firewall.- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Thanks John,

I guess it's safe to say from the drawing Jim Shea posted that the entire box and rag joint is painted to some degree with black.- Top

Comment

-

- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Can anyone tell me the current availability of the 1967 5699250 rag joint and or the later replacement 7806391 rag joint that services the 67-68-69 years. Also, what's the difference between these two parts.

Thanks, Tim- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

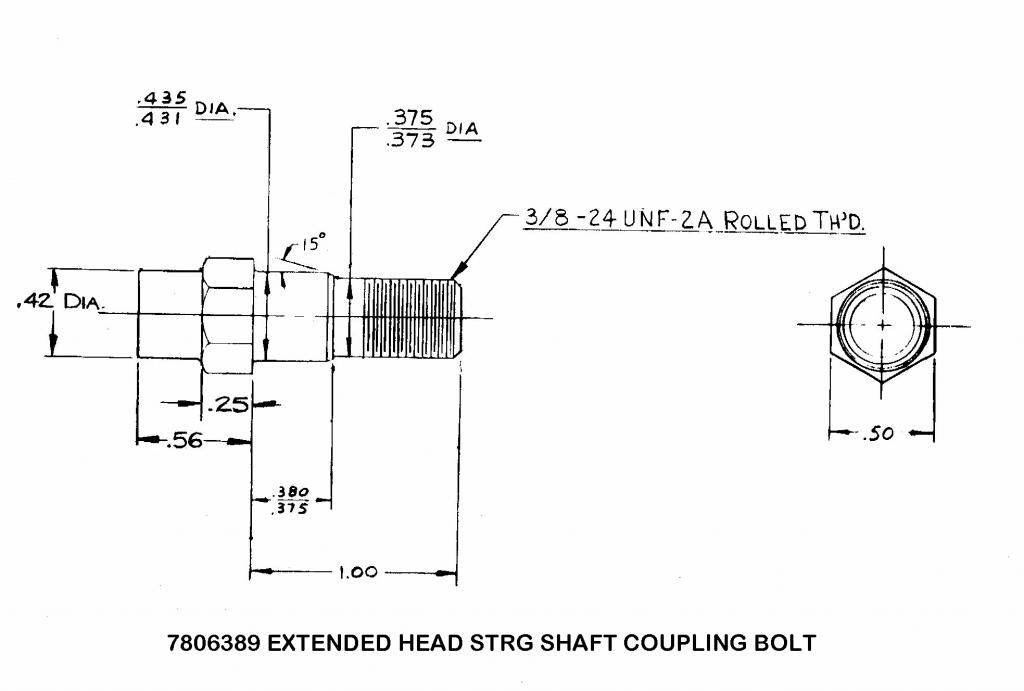

Sorry, I can't help you on availability. I am wondering how particular you want to be in noting the differences between the 5699250 and the 7806391 cplg assemblies. The major difference is that the ..6391 assembly had extended head bolts.

These bolts were introduced on strg shaft cplg asms that were used with energy absorbing steering columns.

It is very difficult to track the flex coupling changes that occurred from 1967 SOP thru the early 1970s for this reason. In 1967 General Motors introduced energy absorbing steering columns. Up until that time, the steering column steering shaft was just one solid shaft from steering wheel to the flex coupling on the steering gear. So there was virtually no concern about the shaft moving. With the introduction of the energy absorbing steering column, the steering shaft was now in two pieces and could telescope on itself. Any motion of the body to the frame could cause the shaft to foreshorten. Now when the body and frame motion relaxed, the flex coupling asm could be pulled apart. This was a new dynamic and required several rapid design changes.

The extended head bolts were added to help insure that the heads of the bolts would make metal to metal contact with the bow tie flange even if the coupling assembly was somewhat pulled apart.

Both coupling assemblies had bow tie flanges (gear input shaft flanges) that had full round splines. So neither of these assemblies would assemble to a Corvette gear with a flat on the input shaft (mid 1969 and later).

The ..9250 assembly was released for production in Nov 1965. Two rubber "rivet caps" were added in January 1966. The caps were removed in March 1967. So I assume the rubber caps were in production for some short period of time. (Possibly early in the 1967 model year.) This drawing was never updated with a screen ground, 7 ply coupling disc. It still shows the brass ground strap.

The ..6391 assembly was released for production in March of 1968. The ground strap was removed and a screen ground 7 ply disc added per revision dated Feb 1971. This was just a service part change, the assembly could not be in production at that late date because the gear input shaft had a flat by that time.- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

I believe they are now both obsolete, the #91 being last available about 2-3 years ago and it was not grounded. It had yellow ink on it.

Jim that bolt print looks like one of my old trade school assignments for lathe work!- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Now that Saginaw is "out of the flex coupling" business directly. (The service business was shopped out.) Nobody is directly covering the shop. And I think that General Motors has even less interest in 40 year old service parts. When I complained about service coupling assemblies not providing any horn ground path, GM's answer was to just cancel the parts. No more headaches that way!!!

I can track revisions to coupling assembly drawings. But the revision dates on the drawing are not the dates when the parts were actually in production. Particularly when there were safety connotations (i.e. coupling assemblies being pulled apart) things could happen very fast. Older parts were updated with the latest designs quite quickly.

Jim- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

John, If the rag joint/coupler came with the steering gear, how were tele rag assemblies handled? Did St. Louis change the rag assemble or simply install a steering box with the appropriate rag assembly?- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

Jim------

There were two different steering gear assemblies, each of which differed only with respect to the installed coupling (rag joint). The assembly line workers installed the one for standard column or tele column, as appropriate.In Appreciation of John Hinckley- Top

Comment

-

Re: Paragon Rag Joint Repair Kit

From 1963 through 1964 there was only one steering column, (the non-adjustable, standard steering column designed by Chevrolet.) So there was only one gear and one flexible coupling attached to the gear for manual as well as power steering.

In 1965 and 1966 there was the standard and the optional telescoping column. The standard column was a Chevrolet design. The telescoping column was a Saginaw design. So early in the development of the Saginaw adjustable columns, the tube size and connections were different between the two types of steering columns. So there were two steering gear assemblies (different by the connection to the steering column steering shaft.) One for the standard and one for the telescoping column. On the Corvette, power and manual steering made no difference.

In 1967 Saginaw became responsible for all GM energy absorbing steering columns. This provided the opportunity to standardize the steering column to flexible coupling connection. So in 1967 and 1968 the connection to the steering gear on the standard and telescoping columns was standardized so we were back again to only one steering gear that was shipped with the flexible coupling attached. Again, no difference power or manual steering.

In 1969 through 1982 the standard column and the tilt & telescoping columns continued to have a standardized connection to the steering gear and only one steering gear with attached flexible coupling was required. Again, no difference between power and manual steering.

Jim- Top

Comment

Comment