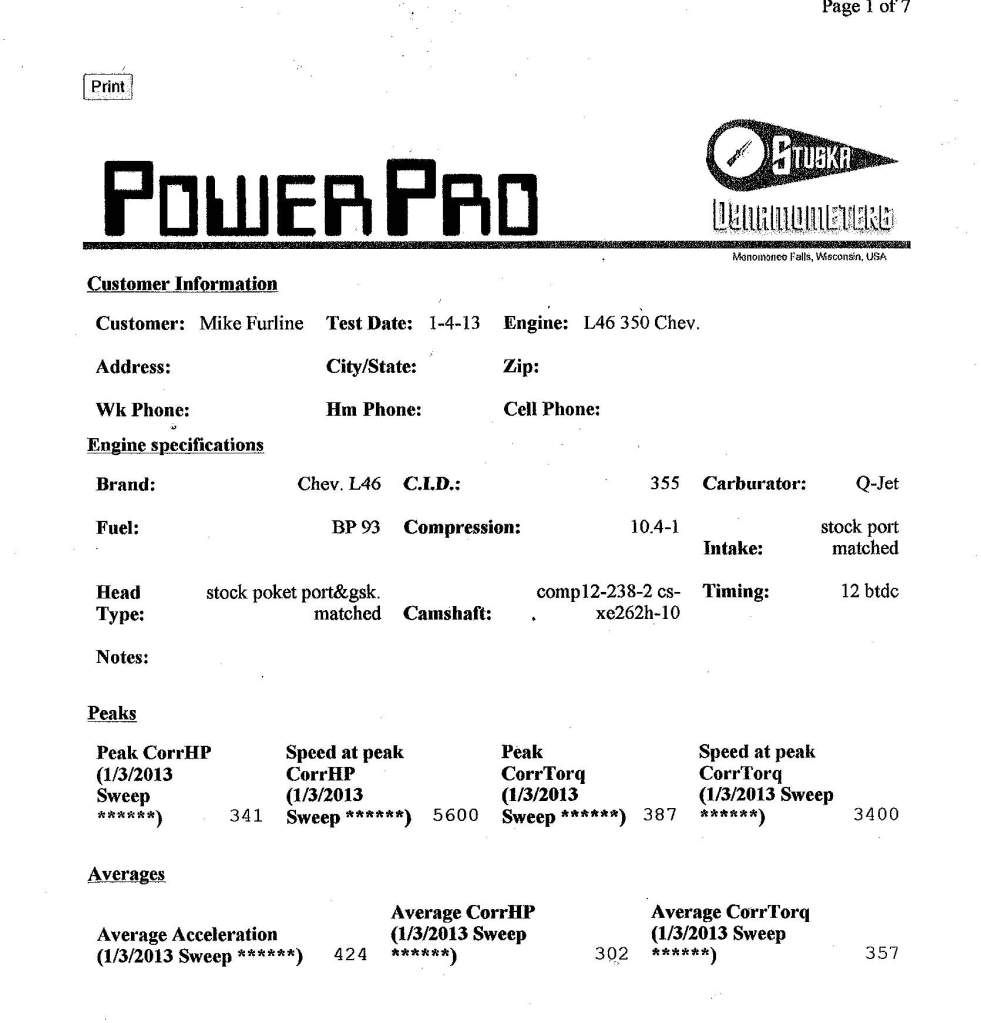

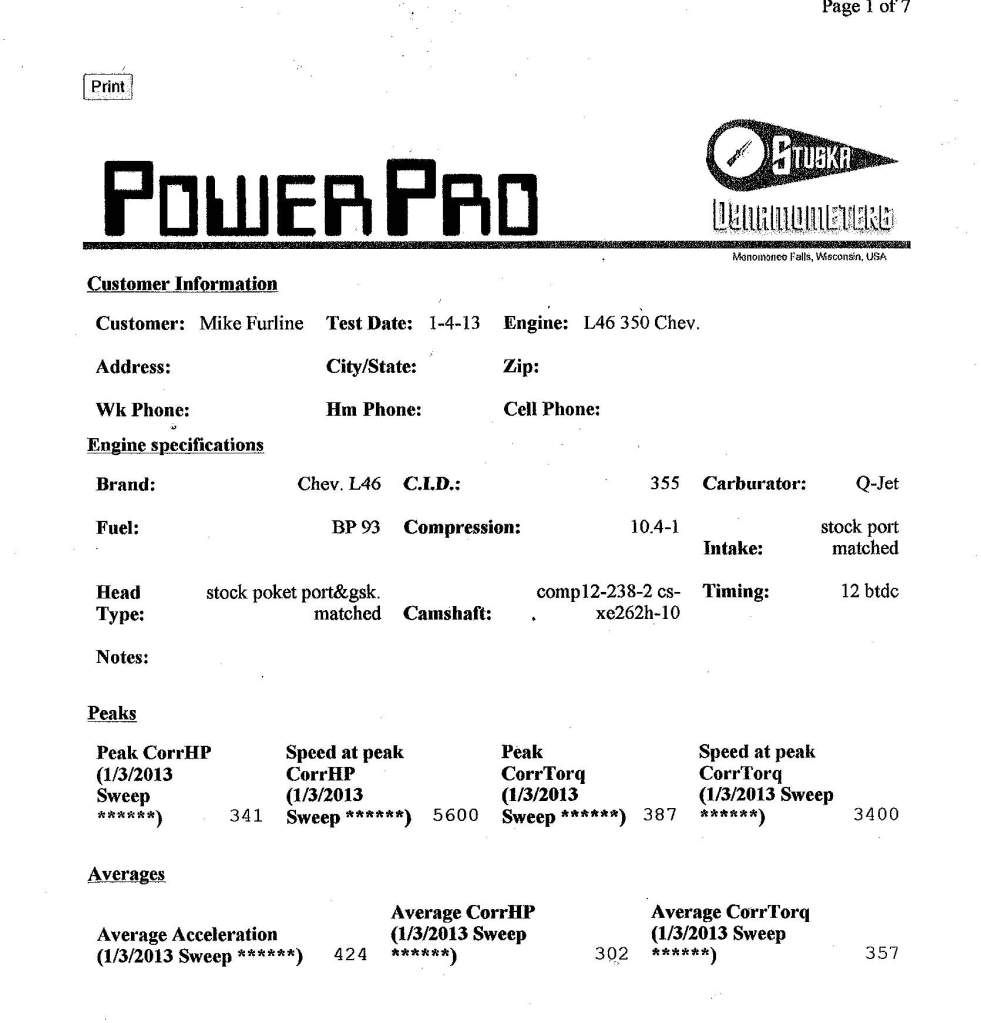

Had the detuned L-46 rebuilt and brought back closer to the original specs. Forged pistons .030, Comp cam, heads ported, .........

(L-46 Dyno Runs Part 1 here, https://www.forums.ncrs.org/showthre...ight=l-46+dyno )

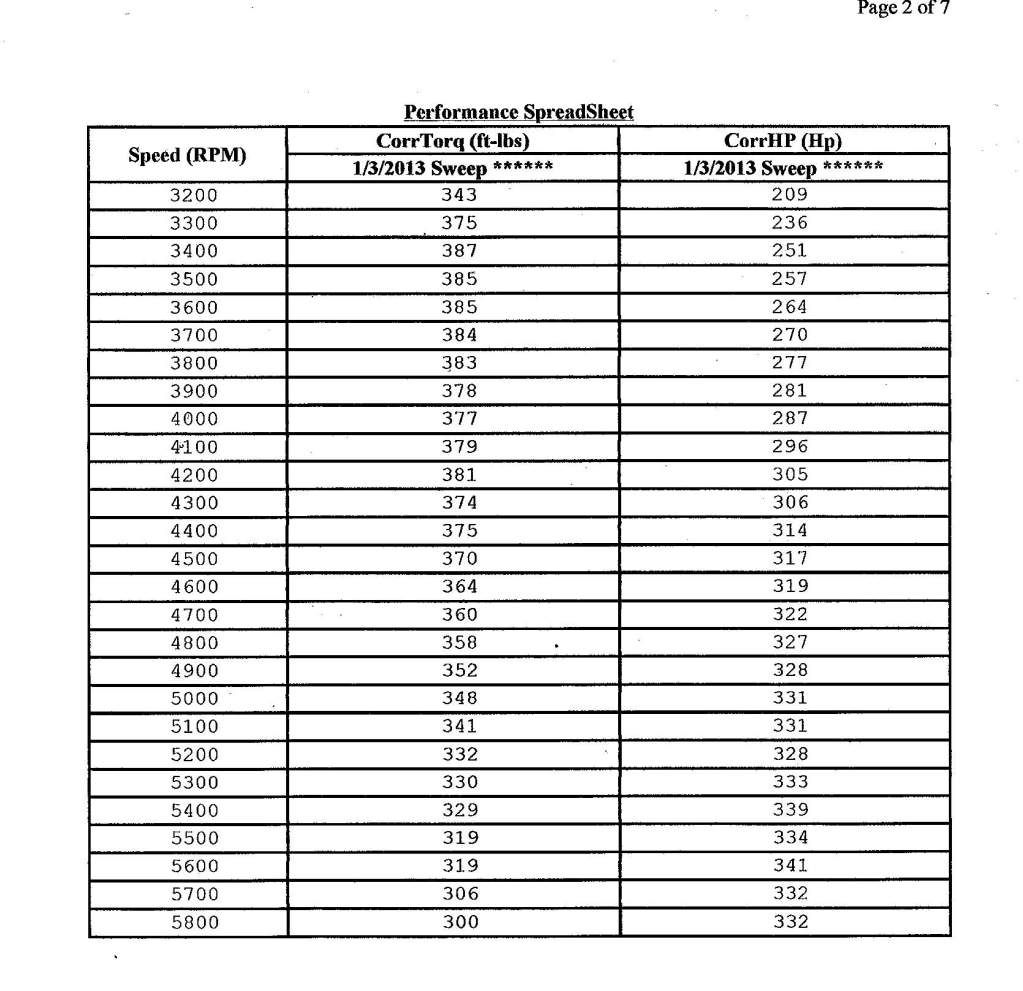

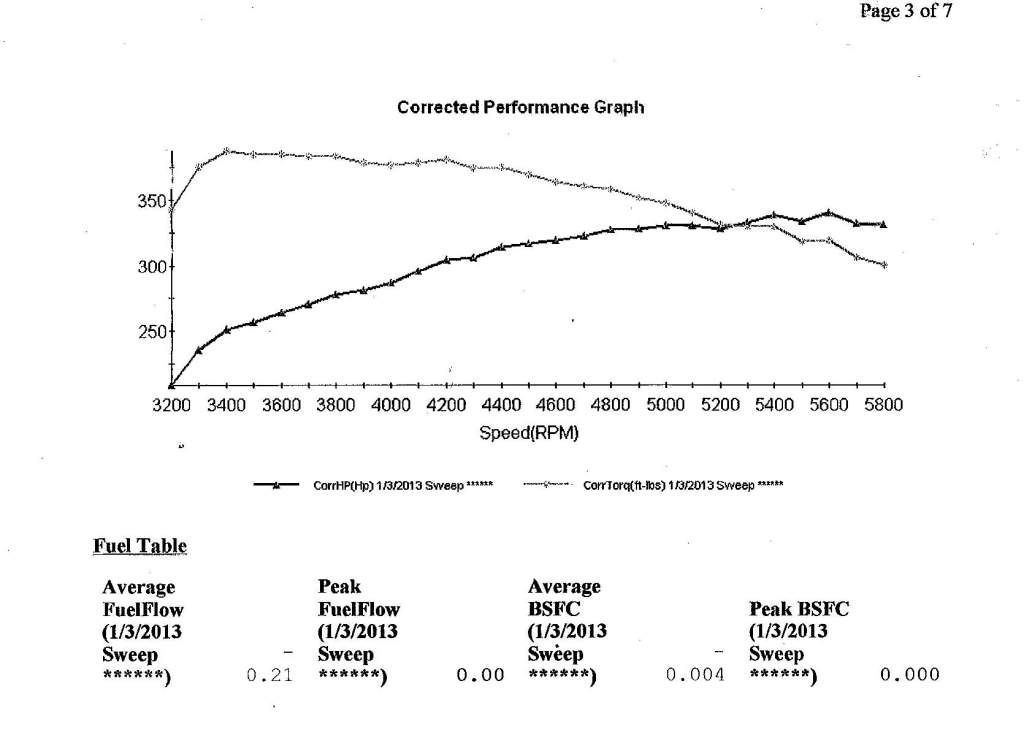

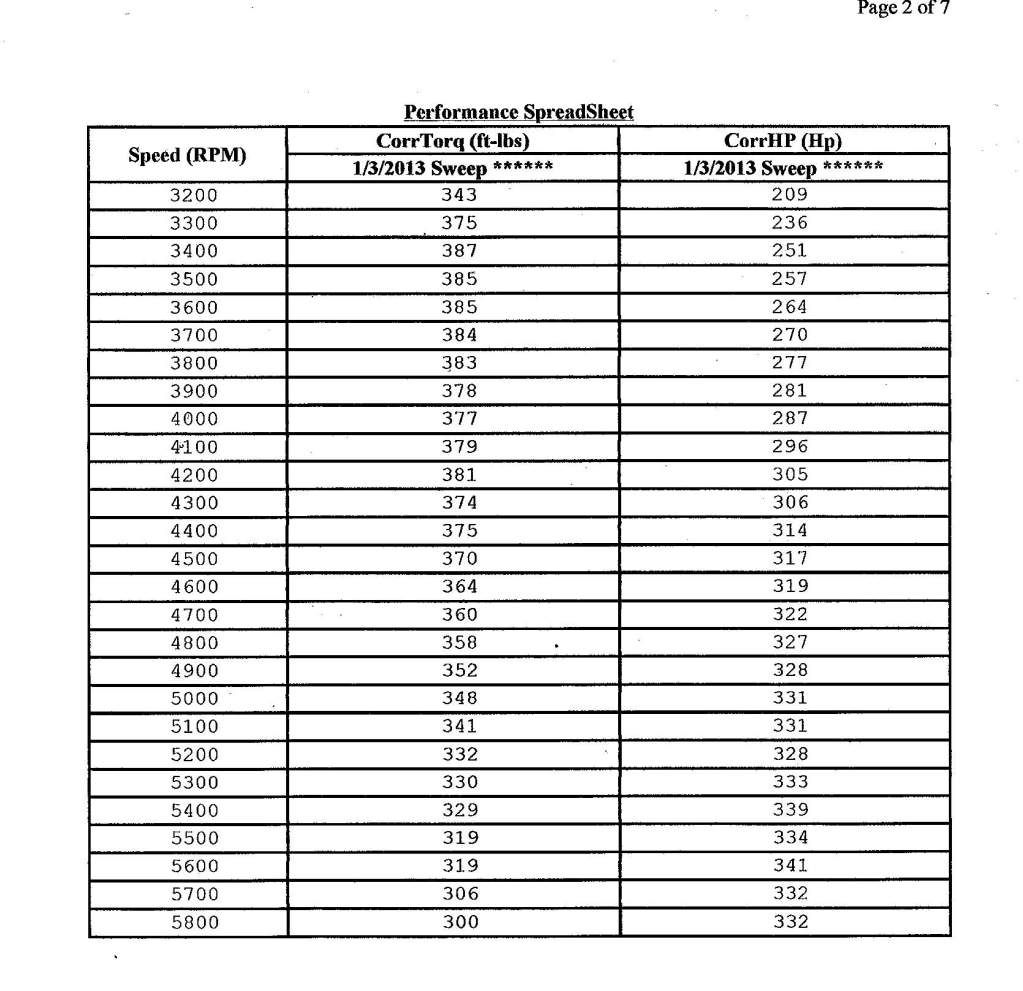

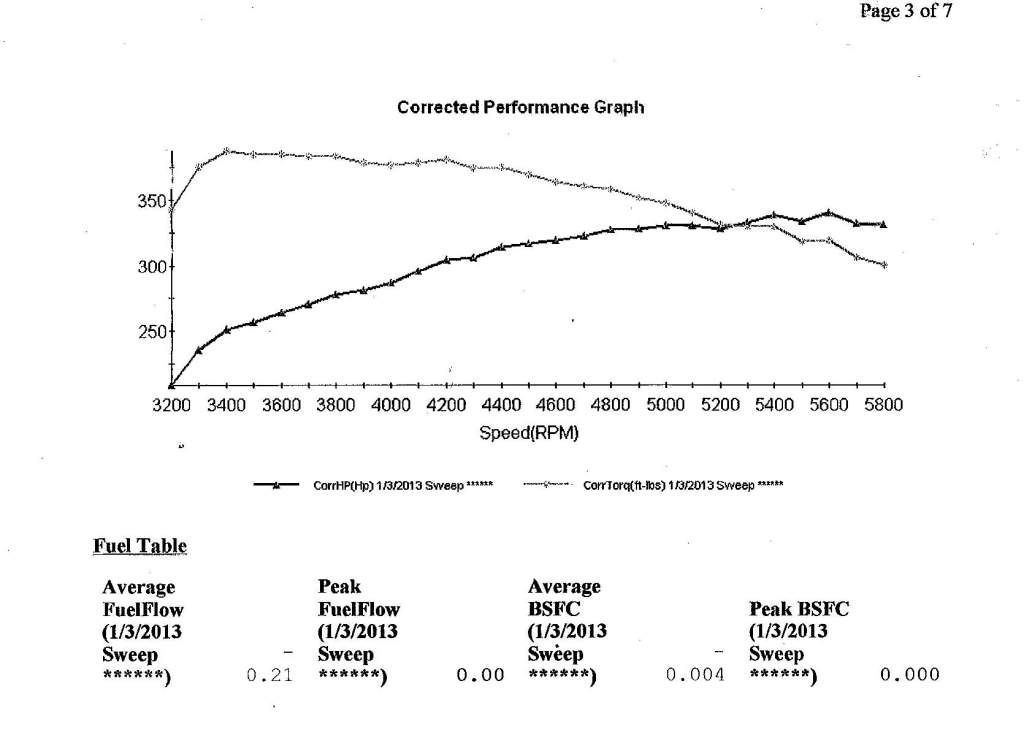

Engine Lab dyno results

Before - 285hp @ 4900rpm / 336tq @ 3400 / Comp 8.7:1

After - 341hp @ 5600rpm / 387tq @ 3400 / Comp 10.4:1

Here are the Engine dyno numbers. I'll get chassis dyno results when weather permits.

(L-46 Dyno Runs Part 1 here, https://www.forums.ncrs.org/showthre...ight=l-46+dyno )

Engine Lab dyno results

Before - 285hp @ 4900rpm / 336tq @ 3400 / Comp 8.7:1

After - 341hp @ 5600rpm / 387tq @ 3400 / Comp 10.4:1

Here are the Engine dyno numbers. I'll get chassis dyno results when weather permits.

Comment