Re: Alternator Alignment 1963 327/250HP

I've been looking through all the pictures I have and don't have one with a clear shot of an original car (250hp) of the alternator and pulley.

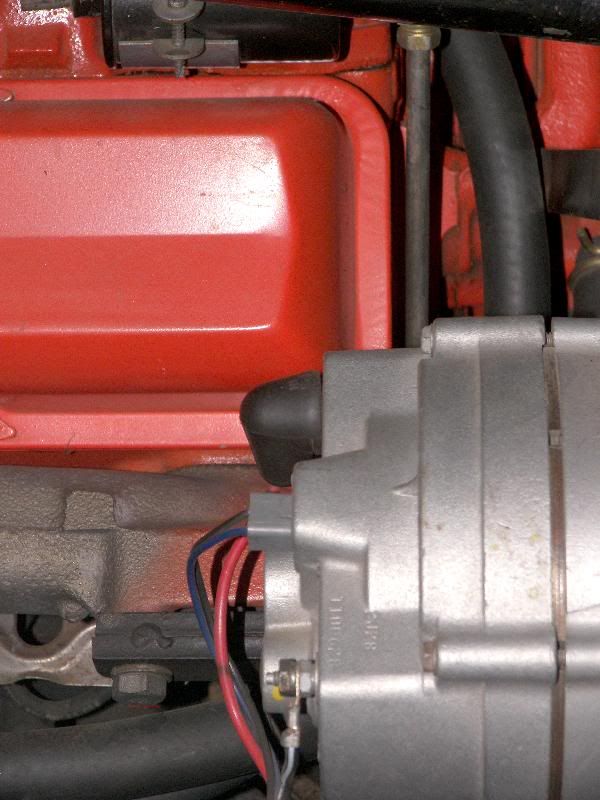

What I can say is that the pulley on your alternator looks identical to the pulley on my alternator on my 250hp 63. I also have the belt on the forward groove.

I did find a picture in a book. If you have "Original Corvette Stingray 1963-1967" by Tom Falconer. Look at page 27. As far as I know that is the correct set-up.

Cheers

I've been looking through all the pictures I have and don't have one with a clear shot of an original car (250hp) of the alternator and pulley.

What I can say is that the pulley on your alternator looks identical to the pulley on my alternator on my 250hp 63. I also have the belt on the forward groove.

I did find a picture in a book. If you have "Original Corvette Stingray 1963-1967" by Tom Falconer. Look at page 27. As far as I know that is the correct set-up.

Cheers

Comment