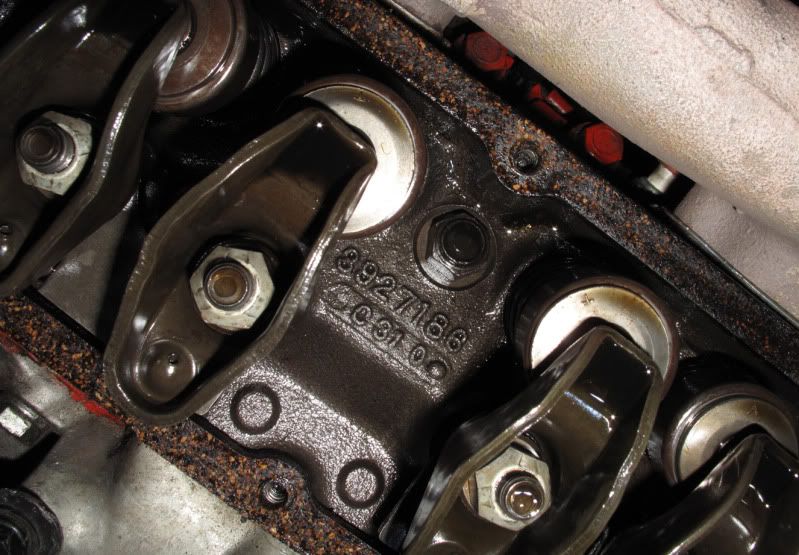

Had the engine apart after doing a compression test--everything looks good (without pulling the heads off) except need to replace the valve seals--look like originals. I was told by a previous owner that he replaced the cam with the original one. Can anyone tell me what the settings are for the intake and exhaust valves. Thanks Paul

1971 LT-1 Valve settings?

Collapse

X

-

Re: 1971 LT-1 Valve settings?

"30-30" AND OTHER OEM SB SOLID LIFTER CAM VALVE ADJUSTMENT

(Revised 12/15/2005)

By John Hinckley and Duke Williams

The traditional method of adjusting valves one or more cylinders at a time with each cylinder at TDC is fine for hydraulics and for most solid-lifter cams, but NOT for the factory "30-30" solid-lifter cam used in '64-'65 L-76 365 HP and L-84 375 HP (FI) Corvette engines (and in '67-'69 Camaro 302/290 Z/28 engines); this cam has VERY long clearance ramps that are .017" high, and at TDC for any cylinder, both the intake and exhaust valve for that cylinder are still on their ramps, NOT on the cam's base circle, which is why the Service Manual for all cars so equipped says specifically to set them "hot and running".

There is, however, a better way to adjust the valves with a "30-30" - you can set them "cold and not running" by setting the intakes at 90 degrees ATDC and the exhausts at 90 degrees BTDC - so the lifters are on the base circle, not on the clearance ramps. This has been confirmed with cam lift/crank-angle diagrams and analysis of the GM drawing lobe data, and I've done mine this way - results in a nice mechanical "singing" sound, no "clacking", it runs better, sounds better, idle is more stable, and throttle response is improved. Several other Z/28 owners have followed this procedure as well since we developed it, and all of them have seen the same positive results.

You can adjust two valves at each 90-degree rotation point, starting at #1 TDC, turning the crank 90 degrees at a time seven times (measure and mark your balancer first at 90-degree intervals from TDC). Removing the plugs simplifies rotating the crank, but you were going to change them anyway, right? Proceed as follows:

TDC #1 - 8E, 2I

90 deg. - 4E, 1I

180 deg. - 3E, 8I

270 deg. - 6E, 4I

0 - 5E, 3I

90 deg. - 7E, 6I

180 deg. - 2E, 5I

270 deg. - 1E, 7I

Start at TDC #1, then rotate 90 degrees at a time, setting at .023" cold. If you like, you can then go back after you're done to each cylinder's TDC position and check clearance on that cylinder's two valves, and you'll find that they've closed up to approximately.021", indicating that both valves are still on the ramps at TDC, as I pointed out in the beginning.

Trivia - the point of max inlet lift on the "30-30" cam is at 110 degrees ATDC and 118 degrees BTDC on the exhaust side, so the lobe separation angle is 114 degrees (angle between points of max lift, not the geometric center of the lobe - the lobes on the "30-30" cam are asymmetrical).

Addendum (May 19, 2003), Lash settings revised 12-14-2005

This indexing procedure on page 1 may be used with ANY cam to assure that the lobe is on the base circle, and MUST be used for cams with very long clearance ramps.

Note: Clearances/clearance ramp heights are listed inlet/exhaust.

Interesting facts: The LT-1 cam exhaust lobe is the same as the 30-30 cam lobe (both sides identical), but the point of maximum lift is indexed four degrees earlier at 122 deg. BTDC. The LT-1 inlet lobe is the same at the L-72 cam lobe (both sides identical), but the point of maximum lift is indexed two degrees later at 110 deg. ATDC versus 108 deg. ATDC for the L-72. The LT-1 inlet/L-72 lobe also has greater asymmetry than the 30-30 lobe. The LT-1 cam was, therefore, not "all new", but incorporated two proven lobe designs with indexing refinement to broaden torque bandwidth, and the early phased exhaust event compensates for the small blocks' relatively restrictive exhaust port. The Duntov lobes are symmetrical and identical other than the exhaust lobe having .004" greater clearance ramp height. At any point on the opening and closing flanks (the portion of the lobe above the top of the clearance ramp), as measured from the point of maximum lift, the design exhaust lobe dimension is exactly .00400" greater than the inlet lobe.- Top

-

Re: 1971 LT-1 Valve settings?

It's discussed in the write-up. The drawing for the 30-30 cam lists clearances of .025/.025, which is 1.5 x .017. So why does all the service literature say .030" in conflict with the engineering drawing? Whatever the reason the .030" clearance was also specified for the exhaust side of the LT-1 cam, which is the same lobe as the 30-30.

On the inlet side the LT-1 lobe clearance ramp is the same height as the exhaust lobe on the Duntov, but the clearance is specified in the service literature as .024" instead of .018", which is 1.5 x .012". Why? I don't know.

My recommended clearances are derived by multiplying the clearance ramp height times the actual lash point rocker ratio. This is the MAXIMUM clearance the engine should see during operation to open/close the valves at clearance ramp velocity, and leaves plenty of margin for any clearance tightening at any operating condition.

If you want to do your own analysis, email me and I will send you the complete LT-1 cam lobe data set and dynamic analysis.

DukeLast edited by Duke W.; September 5, 2008, 09:38 AM.- Top

Comment

-

Re: 1971 LT-1 Valve settings?

hi,

i've been combing the list and the archives for informatin on adjusting the valves for a 1970 lt-1.

i found detailed procedures on how to set the valve lash but came across different numbers concerning the clearances.

oem gm settings engine hot/running are in .024" ex .030"

in different adjustment docs found with engine cold:

1. in .021" ex .026"

or

2. in .016" ex .023"

(this i found in the doc "30-30 and other oem sb solid lifter cam valve adjustment revised 09-23-2008" page 2)

which setting should i use, 1 or 2?

thankseat my dust- Top

Comment

-

Re: 1971 LT-1 Valve settings?

Note that this thread was started in 2006.

The valve adjustment paper was updated in 2008, specifically the following statement.

"With the Duntov cam this indexing procedure may be used, or both valves may be set with the cylinder at TDC of the compression stroke, or all 16 valves may be adjusted at TDC #1 and TDC #6 as outlined in the 1963 Corvette Shop Manual."

THE UNDER:LINED STATEMENT IS WRONG!!!

The #1 and #6 method CAN ONLY BE USED FOR HYDRAULIC LIFTER CAMS.

The first version of this paper in 2003 had different lash setting recommendations that were based on measurements of the cam lobe with a dial indicator. The 2006 version tightened these recommendations and was based on analysis of the lobe data from the GM drawings.

Despite me notifying various Web page owners that earlier versions (2003 and 2006) of this document are incorrect and obsolete, they still remain on the Web.

The 2008 revision is at:

About 90 percent of those who have used these settings are happy with them. They will affect idle quality depending on where the valves were set prior to adjustment, because these settings increase effective overlap slightly, however, on the upside, they don't beat up the valve train.

After setting the valves one should go through the idle speed/mixture adjustment. In general, I recommend an idle speed of 900 RPM for all mechanical lifter cams and add 100-200 for Fuel Injection.

Idle speed is somewhat subjective. As one reduces idle speed, idle quality deteriorates, so set idle speed as low as possible commmensurate with acceptable idle quality, which will vary from individual to individual. I don't like a very lopey idle, so I tend to set idle speeds on the high side. IMO Chevrolet's recommended idle speeds for mechanical lifter cams are unreasonably low.

DukeLast edited by Duke W.; August 13, 2010, 11:46 AM.- Top

Comment

-

Re: 1971 LT-1 Valve settings?

I haven't changed the lash recommendations since the '05 revision.

They apply to the OE rockers.

I have no idea how your Mickey Mouse aftermarket rockers behave, so you're on you own or get some OE rockers and lash them per the '08 revision.

Duke- Top

Comment

-

-

-

Re: 1971 LT-1 Valve settings?

How can you determine if you have a 30-30 cam or a Duntov cam without taking the engine apart to look at the part number. I bought my cam used and was told that it was a 30-30 cam. after I installed it, the idle did not seem as rough as the 30-30 cam engines that I have heard. I suspect that it is a Duntov cam.- Top

Comment

-

Re: 1971 LT-1 Valve settings?

There are a couple of ways. First is to just check idle vacuum at 900 with total idle timing of about 28-32 degrees, which is the sum of full vacuum advance attaintable from the 236/B28 VAC, about 12 initial, and maybe, a few degrees centrifugal since some SHP centrifugal curves start at about 700.

The Duntov and LT-1 cams pull about 12" at these conditions and the 30-30 about 10".

The "for sure" way is to measure lobe lift. Remove one inlet and one exhaust rocker arm, set up a dial indicator on the pushrod as close to in line with it as you can eyeball, find the base circle zero the indicator and turn the engine until you achieve peak lift.

Duntov: .2625/.2665"

30-30: .323/.323"

LT-1: .306/.323"

Duke- Top

Comment

-

Re: 1971 LT-1 Valve settings?

well hi again,

i measured the cold valve clearance that the motor had--i got .040" on the exhaust side and about .034" on the intake.

today after fiddling around for over an hour with 2 re-checks, i set the valve lash to .021" on the intake and .026" on the exhaust (corvette enthusiast article).

i'll take the car out for a ride this weekend. if everything runs fine i'll set the lash settings to .016" and .021". still have to torque the plugs.

or should i go straight to .016" and .023"? i'm a cautious type.

Last edited by Wolf S.; August 20, 2010, 02:31 PM.eat my dust

Last edited by Wolf S.; August 20, 2010, 02:31 PM.eat my dust- Top

Comment

Comment