In the process of refurbishing the rag joint on my '65, non-telescoping, non-power steering coupe. Referring to the '63 Corvette Shop Manual, section 9.4 in the text, references a mark on the wormshaft designating steering gear high point. Referring to the attached photo of the input shaft on my steering gear box, is the small rectangular mark at the 12 o'clock position on the end of the shaft, the mark being referred to in the shop manual?

Steering Wheel Alignment and High Point Centering

Collapse

X

-

Re: Steering Wheel Alignment and High Point Centering

Yes, it is the high point but please make sure it is not turned to the right or left. Make sure that there is as much movement to the right as to the left by rotating the shaft in both directions before you attach the rag joint. Then the steering wheel shaft should align with the mark on the steering wheel hub to the top also.

JR- Top

-

Re: Steering Wheel Alignment and High Point Centering

Hi Joe

Thanks for the response to my post. Continuing on a bit in my questions around alignment marks, the service manual states that the alignment mark on the input shaft to the steering gear box should be "at 12 o'clock and lined up with the mark in the coupling clamp". I believe my rag joint is original to the car (upper and lower clamps carry a stamping of 5686624). I have media blast cleaned these parts carefully but I do not see any obvious mark on either of these clamps. In other papers written on this topic, I have seen a reference to using the "saw line" which I believe is the clamping gap on the piece as the reference line for setting high point centering. Is that correct?- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Jim,

Yes, the "saw line" would be the reference with the clamping gap. That would put the steering shaft flat on top and the "saw line" on the upper steering shaft should be at 12 o'clock at the steering hub.

JR- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Jim, I would also do a visual inspection to make sure the front tires are pointing straight ahead and the steering wheel is also centered when complete. if not the toe adjustment may have to be corrected, The rag joint and front tires must be centered so have the best possible feel when traveling straight ahead.New England chapter member, 63 Convert. 327/340- Chapter/Regional/national Top Flight, 72 coupe- chapter and regional Top Flight.- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

The steering box should have a little resistance as you turn it through its center point. The flat spot mentioned will be on top when the resistance is felt. I am not sure if you can feel the resistance by turning it with the steering wheel. Mine is currently removed and the resistance is very obvious. Older boxes may not be so obvious due to internal wear. Then to be sure, count the turns in both directions to double check the steering box.

Bill- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Some observations from building these boxes for years. Many times the chisel mark or D flat on the input shafts are not on true center. They may be on high center, meaning the highest point of lash. Text book would be both high & true center be the same at 12 o'clock, however many are off.

From the lone picture of the box in question it appears to show age. As mentioned you would feel a box snug up on center by hand but the best way to check it is with a 0-30 in/lb dial torque wrench. With the box out of the car you can see exactly where the high center is and reference it to the chisel mark. The D-Flat coarse spline inputs start late in 1969 thru 1982. The 63-e69 used the fine spline full shafts.- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Thanks Ed... I note that when the gearbox input shaft is at the 12 o'clock position the front tires are not exactly pointed straight ahead. Will inspect under the car to look at the steering linkage this morning.- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

High Gary

Thanks for the guidance. If in fact the high point and true center are not exactly at the same point, what is the correct set-up procedure? (i.e. set to true center, set to high point, split the difference??)

Jim- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Hello again Gary,

I find that when I have the front wheels pointed straight ahead, there is an equal number of turns (as best as I can measure) on the input shaft clockwise and counter clockwise from left stop to center and right stop to center. The high center mark on the end of the input shaft is about 30 degrees left of center however when I have the wheels set to straight ahead.

I do not have any history on this steering gear box as to whether or not it has ever been rebuilt. When I turn the input shaft using the rag joint clamp fitted over the splined end of the shaft, I can feel some "growling" in the linkage but no real binding of any kind. I am not able to feel the "high point" when the shaft mark is near the 12 o'clock position. Are there any other things I should be looking for to determine the integrity of the steering gear box?

Jim- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Hi Jim,Hello again Gary,

I find that when I have the front wheels pointed straight ahead, there is an equal number of turns (as best as I can measure) on the input shaft clockwise and counter clockwise from left stop to center and right stop to center. The high center mark on the end of the input shaft is about 30 degrees left of center however when I have the wheels set to straight ahead.

I do not have any history on this steering gear box as to whether or not it has ever been rebuilt. When I turn the input shaft using the rag joint clamp fitted over the splined end of the shaft, I can feel some "growling" in the linkage but no real binding of any kind. I am not able to feel the "high point" when the shaft mark is near the 12 o'clock position. Are there any other things I should be looking for to determine the integrity of the steering gear box?

Jim

With an original 59 year old box that may have been worked on in the past I doubt you will feel it snug up. The chisel mark may be the high center but the only way to tell is checking it with the dial TW.

The box should be smooth from lock to lock, snug up on center and drop back off.

If you want post a picture of the cover of the box I can take a look for you but look at the lash screw to see how many threads are showing above the jam nut. There should be 1-2, rarely are there more. If there are no threads showing that typically means the box was adjusted at some point in the past and the gears could be near bottoming out. Now there is an exception to this check, some of the mid 60's boxes setup low but it's is good general check.

Look at the lock ring for signs of punch marks where someone played with that adjustment- which is almost impossible to dial in with the box on the car.

Lastly how does the car steer, can you steer it or are your aiming it when driving. I have had countless guys tell over the years they have a lot of play in the steering wheel and were told that was normal for an old car. They were told that by the sellers and by rebuilders. Of course that is not true, the cars were great steering and handling new. It's like the disc brake system, it functioned fine until someone who didn't know or care about what they were doing worked on the car, then all bets are off. Speaking of some rebuilders, I see a lot of "rebuilt" boxes come my way because the owners were told the boxes weren't too good. I have found gear teeth welded, rag joints welded to inputs, Worm nut purposely installed upside down to try and compensate for worn teeth, and others that were painted and either overfilled with grease or no grease at all installed. There is a vendor out there still installing the worm nuts upside down. Another thing to keep in mind, Corvette Steering had the gears made for the 63-82 boxes and supplied just about all the vendors. When Tom died, 3-4 years ago I bought his stock of new gears. Not one vendor/rebuilder ever asked me to sell them new gears for their work. The rash of poor service opened the doors for the rack and jeep box conversions when in fact a correctly built Saginaw box will compete with both of them and fit the car correctly. Sorry got off the subject a little but this info should help others as well.

I am willing to bet your box needs attention, the growling could be just the bearings but these boxes do draw in hot air and the old grease can become hard and caked up or turn into an acidic mess that attacks the ball screw of the worm. Many times I find boxes with good lash but the preload on the new bearings is bad, the needle on the TW jumps 2-3 in/lb. This is caused by a worn radius on the ball screw for the end bearings. When I fit a new worm assembly they dial in smooth with little if any needle fluctuation. Also these gear sets are not matched like a ring & pinion. They are separate and the parts were once sold separately. Many times when fitting new gears I will go through several to get th fit I want and dial in the centers. In you case I would like to see where your high center is and go with that. Once in the car the box never travels full lock to lock, it is referenced from center not end.

If you have anymore questions feel free to contact me and I can go over them with you.

Gary- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

Jim, The tie rods are likely going to have to be adjusted to point wheels straight ahead, this should be done on a alignment machine. and you'll likely want to make sure to tell the Tech what your trying to accomplish. another thing is what kind of shape is the box in and how's your steering parts and ball joints, because this is something you only want to do once and do it right. Sometimes with old cars its like opening a can of worms.New England chapter member, 63 Convert. 327/340- Chapter/Regional/national Top Flight, 72 coupe- chapter and regional Top Flight.- Top

Comment

-

Re: Steering Wheel Alignment and High Point Centering

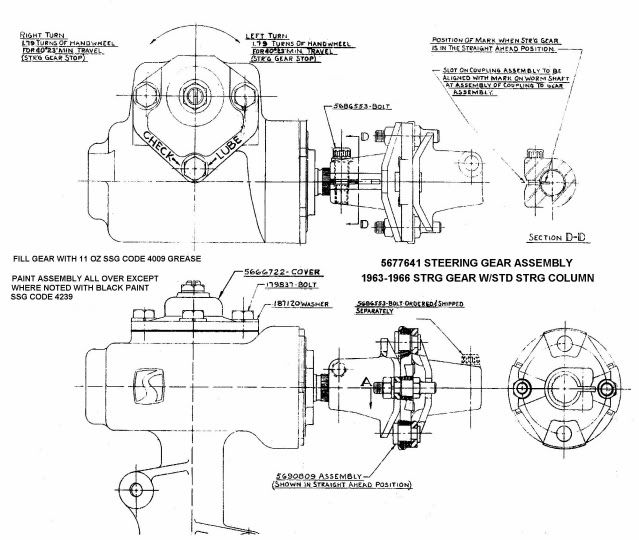

Just a point of information. The 1963 steering gear assembly was shipped from Saginaw with the flexible coupling assembly attached to the gear input shaft. The steering gear assembly drawing states the following: "Slot in coupling assembly to be aligned with mark on worm shaft at assembly of coupling to gear assembly." With the gear on-center, this would place the pinch bolt that attaches the coupling to the gear to be horizontal and passing over the 12 o'clock position. Since Saginaw made that connection the pinch bolt head was easily reached with a torque controlled wrench. This also placed the pinch bolt that attached the coupling to the steering column flange as vertical and passing through the 3 o'clock position. By leaning over the driver side fender, the St. Louis assembly worker could fairly easily reach the head of this bolt that was sticking straight up at him.

Jim- Top

Comment

Comment