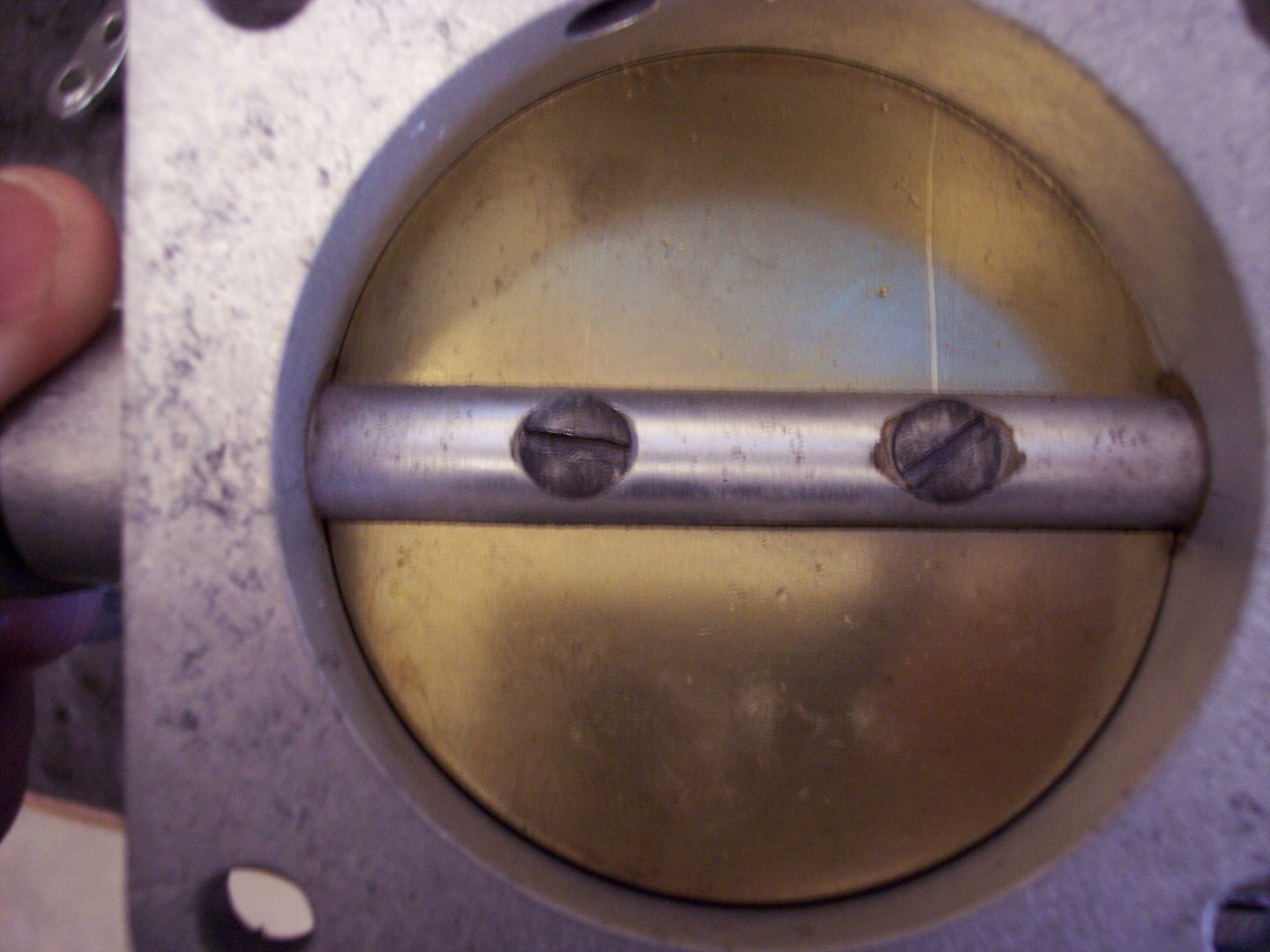

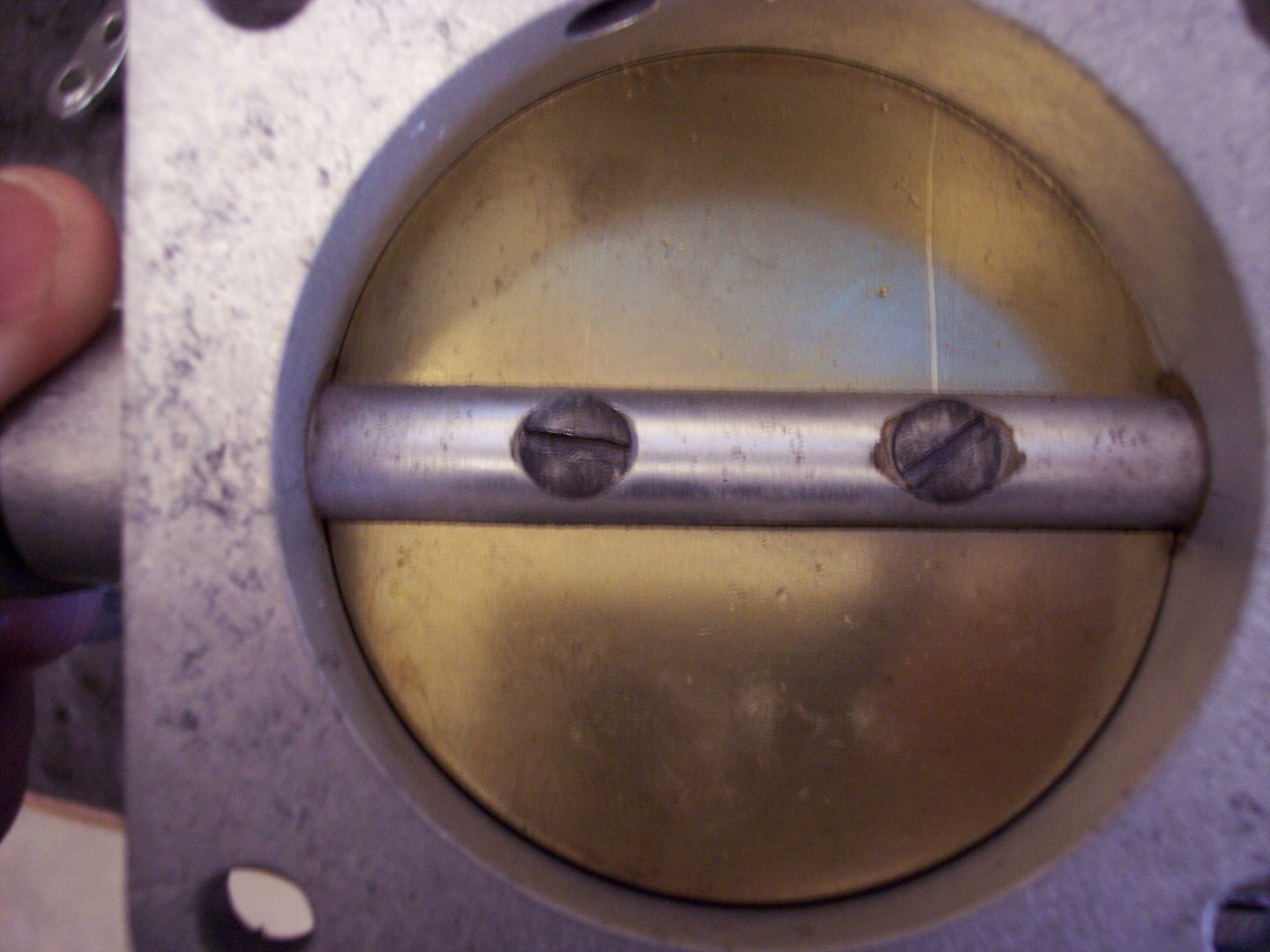

I have been finishing up the injection install on my 62. I am dealing with a unknown unit. The car fired up just fine and kicked to high idle. After warming, I cannot get the car to idle down. I do not believe I have any vacuum leaks. So, I have 2 questions. See the picture below. Is the clearance on the bottom of the throttle blade enough to cause my high idle? Plus, what does a person have to do in order to break loose the 2 screws? I cannot budge them. Thanks!. Tim

Thanks!. Tim

Thanks!. Tim

Thanks!. Tim

Comment