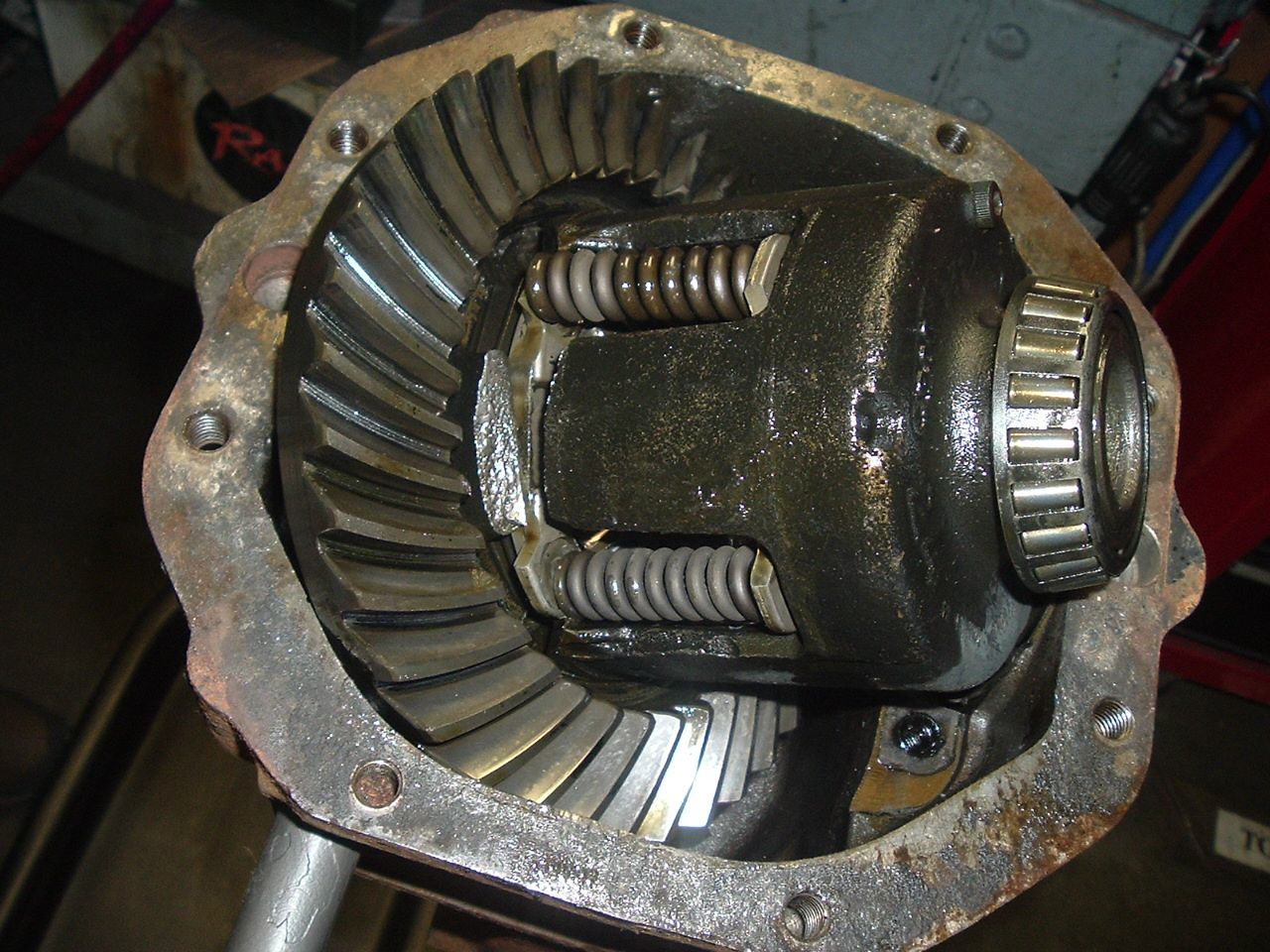

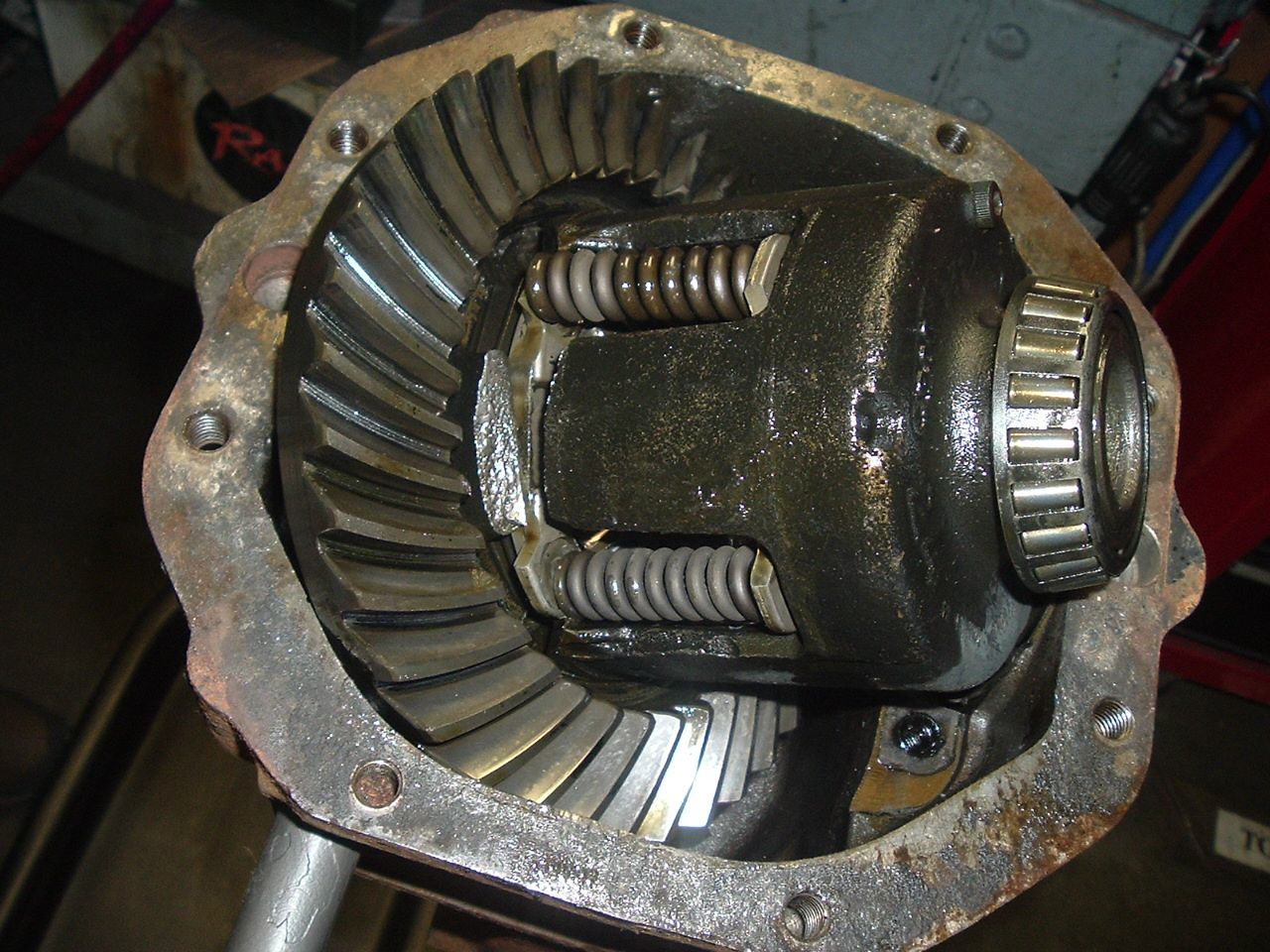

On another thread I was speaking of how the 63-79 posi cases are now obsolete and ended up talking about a 63. Well as fate will have it, a local guy brought in an original 63 diff today that he hear a loud bang out of while driving his 340hp roadster. I was hoping it was worked on in the past and upgraded but as soon as I pulled the cover I saw the dreaded Dana posi. You can see how these are different then the Eaton posi's. The case, springs,plates, spiders, and clutches are all different and for a lack of a better word- junk.

While turning it I saw the ring gear had a LOT of lash and the gear and posi case had different movement. You can see when I got the case out it was the 2-piece design! Yup cracked it in half after years of use.

You can see when I got the case out it was the 2-piece design! Yup cracked it in half after years of use.

The original side yokes are prefect after 50 years. NO wear on them at all, .200" from the face to snap rings. These are better then ANY new or rebuilt yoke on the market today.Anyway since we were talking about this subject the other day I figured some of you would like to see what I was talking about.See ya

The original side yokes are prefect after 50 years. NO wear on them at all, .200" from the face to snap rings. These are better then ANY new or rebuilt yoke on the market today.Anyway since we were talking about this subject the other day I figured some of you would like to see what I was talking about.See ya

While turning it I saw the ring gear had a LOT of lash and the gear and posi case had different movement.

You can see when I got the case out it was the 2-piece design! Yup cracked it in half after years of use.

You can see when I got the case out it was the 2-piece design! Yup cracked it in half after years of use. The original side yokes are prefect after 50 years. NO wear on them at all, .200" from the face to snap rings. These are better then ANY new or rebuilt yoke on the market today.Anyway since we were talking about this subject the other day I figured some of you would like to see what I was talking about.See ya

The original side yokes are prefect after 50 years. NO wear on them at all, .200" from the face to snap rings. These are better then ANY new or rebuilt yoke on the market today.Anyway since we were talking about this subject the other day I figured some of you would like to see what I was talking about.See ya

Bob

Bob

Comment