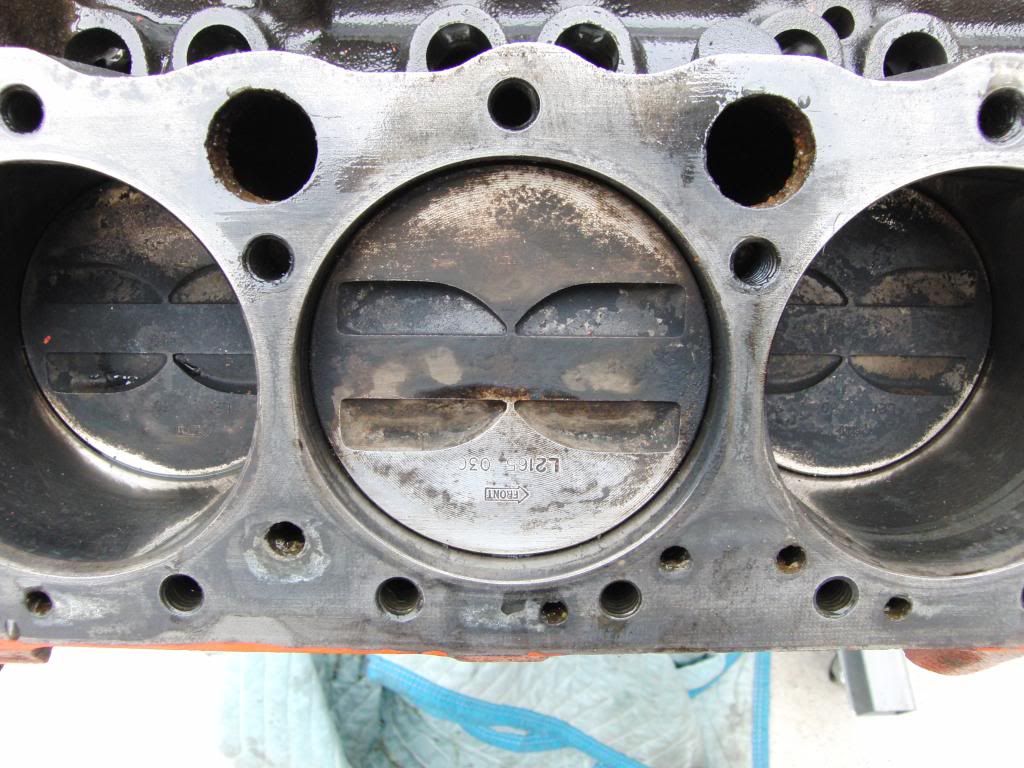

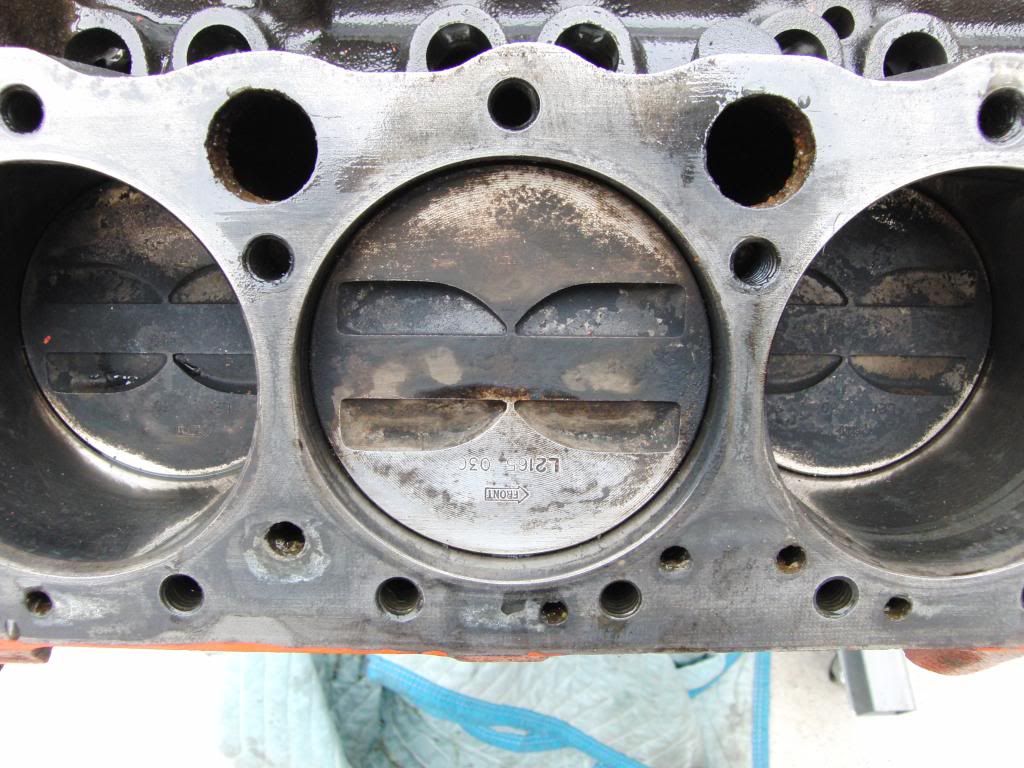

I recently pulled the original engine on my 62 because of some running problems and just decided to rebuild so I know exactly what i have. I found it had been bored .030 over with flat top pistons and a solid cam, but not sure what. The balancer is not original as it is not finned and the oil pan is a replacement although it is a 5 quart (6 quart system) and is baffled and has a trap door. I also found that the decks still have the factory broach marks and included a picture with my stamp pad although it didn't come out very good.

I have been reading up on the archives of this board and my plans for the motor are to replace the pistons with stock at whatever bore we end up with. Replace the stock rods with either the Eagle's or Crower's, pocket port the bowls and port match the intake and exhaust. I am going to run the LT-1 cam as it seems through reading here it will perform better than the 097, especially with 93 octane, with less chance of detonation. I will shoot for a compression ratio of 10-10.5 to one which should be easy with an undecked block. No hardened valve seats, no decking or align boring unless we find something really out of wack. I assume the LT-1 cam will run fine with my stock "397" intake and 3269S AFB.

Thank you Duke Williams and many others for the excellent info found in searching this site, awesome stuff!

I would love to hear anyone's thoughts on anything I may have missed. Thanks in advance. Off to the machine shop tomorrow. Here are a couple of pics.

I have been reading up on the archives of this board and my plans for the motor are to replace the pistons with stock at whatever bore we end up with. Replace the stock rods with either the Eagle's or Crower's, pocket port the bowls and port match the intake and exhaust. I am going to run the LT-1 cam as it seems through reading here it will perform better than the 097, especially with 93 octane, with less chance of detonation. I will shoot for a compression ratio of 10-10.5 to one which should be easy with an undecked block. No hardened valve seats, no decking or align boring unless we find something really out of wack. I assume the LT-1 cam will run fine with my stock "397" intake and 3269S AFB.

Thank you Duke Williams and many others for the excellent info found in searching this site, awesome stuff!

I would love to hear anyone's thoughts on anything I may have missed. Thanks in advance. Off to the machine shop tomorrow. Here are a couple of pics.

Comment