I jacked up my rear end to replace the pinion seal and found the driver side gear yoke had come out 3/4 inch from the differential housing.

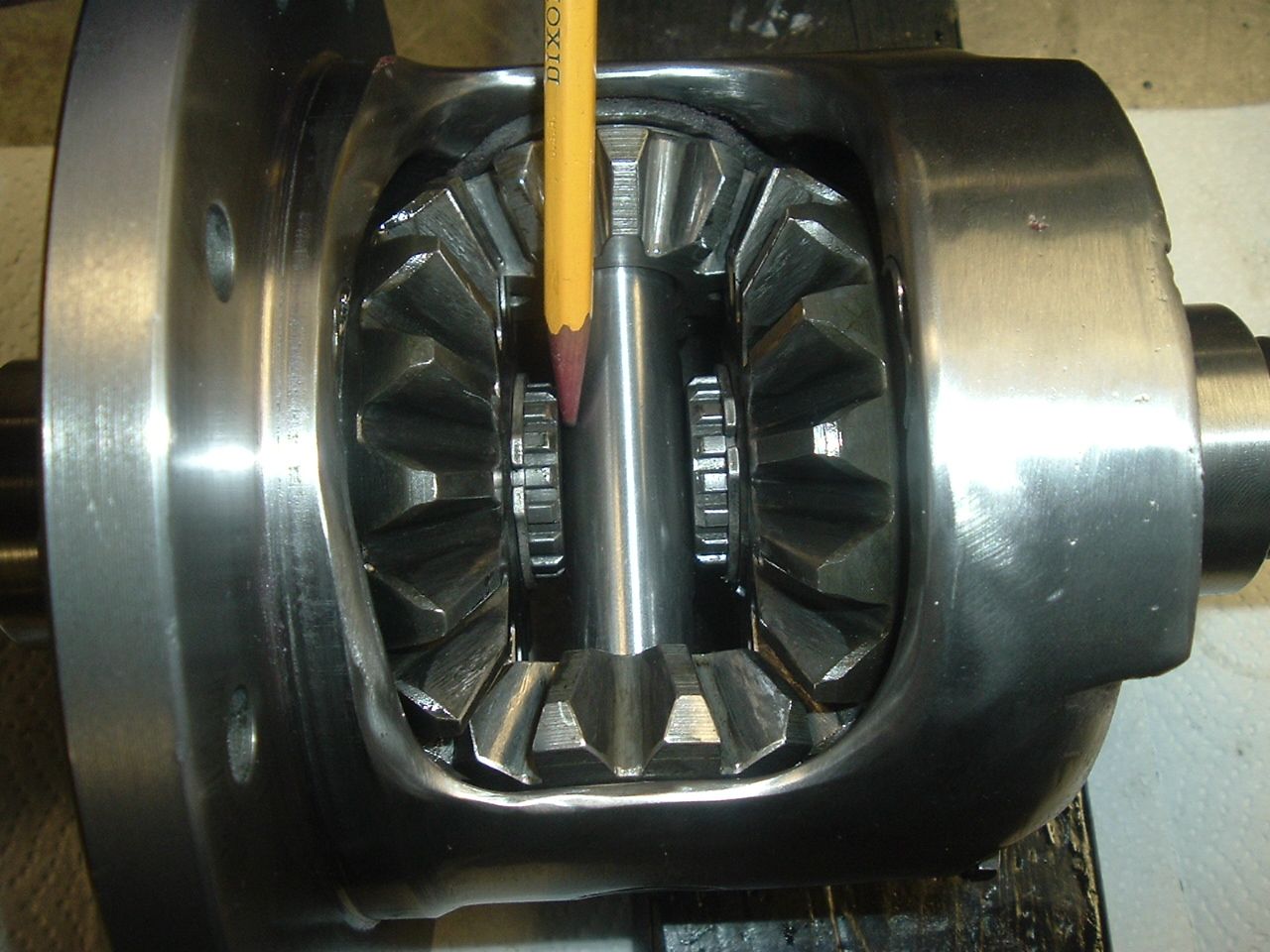

I assumed the C clip had come off. I tore it down and saw the C clip intact up by the pinion gear . not damaged. I'm not sure what to do next ?

I don't see a measurement from the Differential Pinion shaft to the end of the Side gear yoke. Their was no sound coming from the gears.

Thanks for any or advice

I assumed the C clip had come off. I tore it down and saw the C clip intact up by the pinion gear . not damaged. I'm not sure what to do next ?

I don't see a measurement from the Differential Pinion shaft to the end of the Side gear yoke. Their was no sound coming from the gears.

Thanks for any or advice

Comment