Just figure I would pass along some info, maybe most know maybe not?

If you plan on rebuilding or sending out your diff, take the time to check the yokes(axles) especially if you have a 63-73 that is original. I check everyone I get in but you may find some places figure them in as part of the job. With a 74-79 it is very possible they're worn, they weren't anywhere as good as the 63-73-74's were. Most of the 74-79's had soft faces that wore away and caused some issues. If let go too long they will wear down and grind into the carrier and if it hits the seal then you could lose the carrier all together.

I just finished up a '66 BB diff for a fellow NCRS member and although someone was in this diff before the axles were original. Not only original but the best I've ever seen, better then the current New or rebuilt in fact.

As with most diff's this one had axle endplay, about 050-060". A lot of guys assume the axles are the cause and many times they are, but you really do have to check them and see. When I removed the axles and checked them they were in fact longer then any I've had in, new,rebuilt or original. I don't know the exact spec, if there is one, for the distance from the face to the snap ring- I always look for .180-.187. I had a discussion with someone recently who told me it was supposed to be .170-.175 which is shorter then I like to use. Joe L, John H if you know of this spec please let me know.

With this set of yokes they were dead on .200" and not the cause of the endplay. The stock posi was the cause and typically sloppy, as are the new in the box ones today. I did some machining and fitting and now these yokes are good to reuse & for a long time I might add. I set the endplay to 005-008".

So check yours before you ship it, it could save you $200+ alone. If the endplay is excessive check it when you get it back, if done correct it will be in the 005-008 range- regardless of original,rebuilt,or "new".

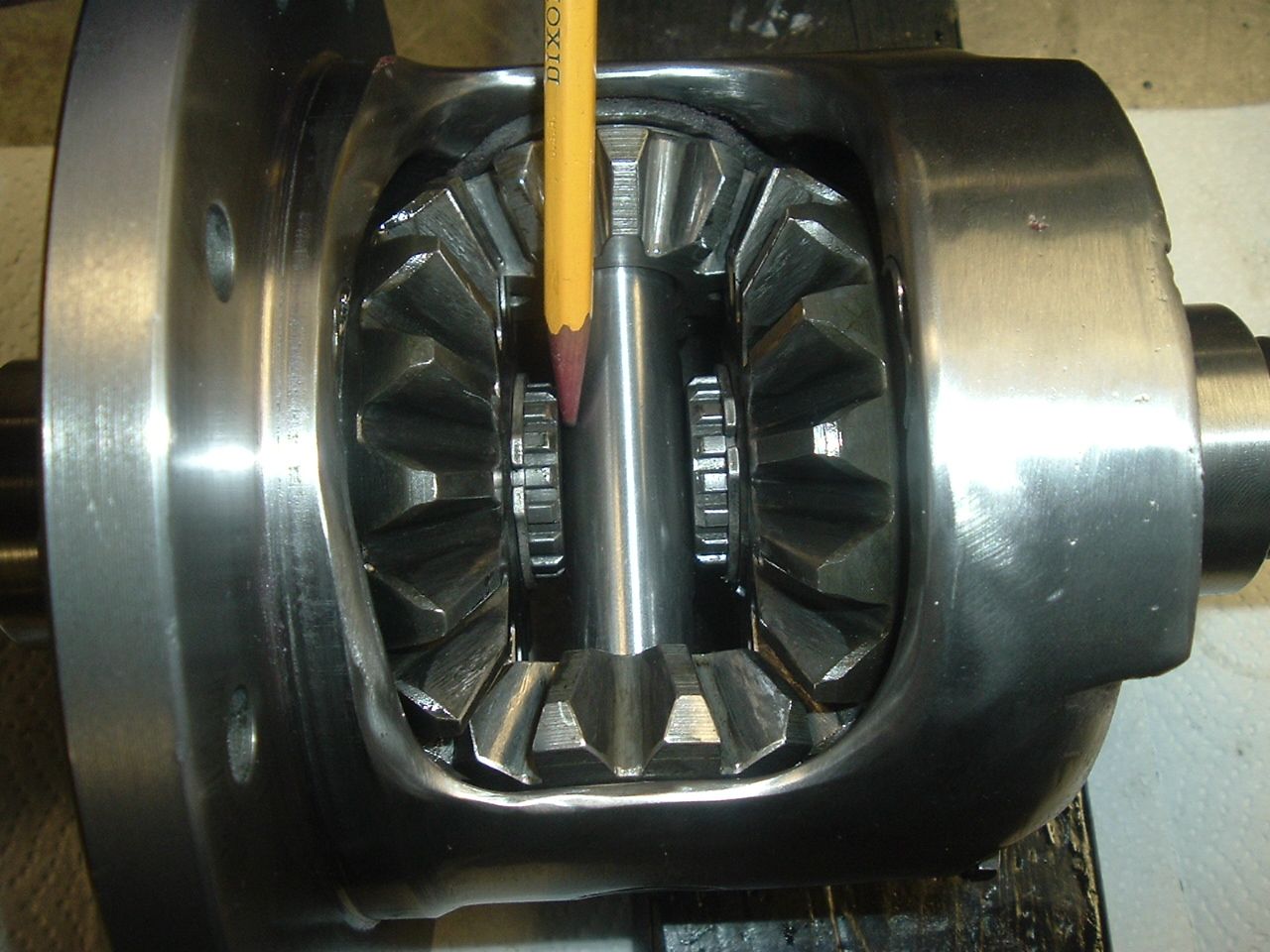

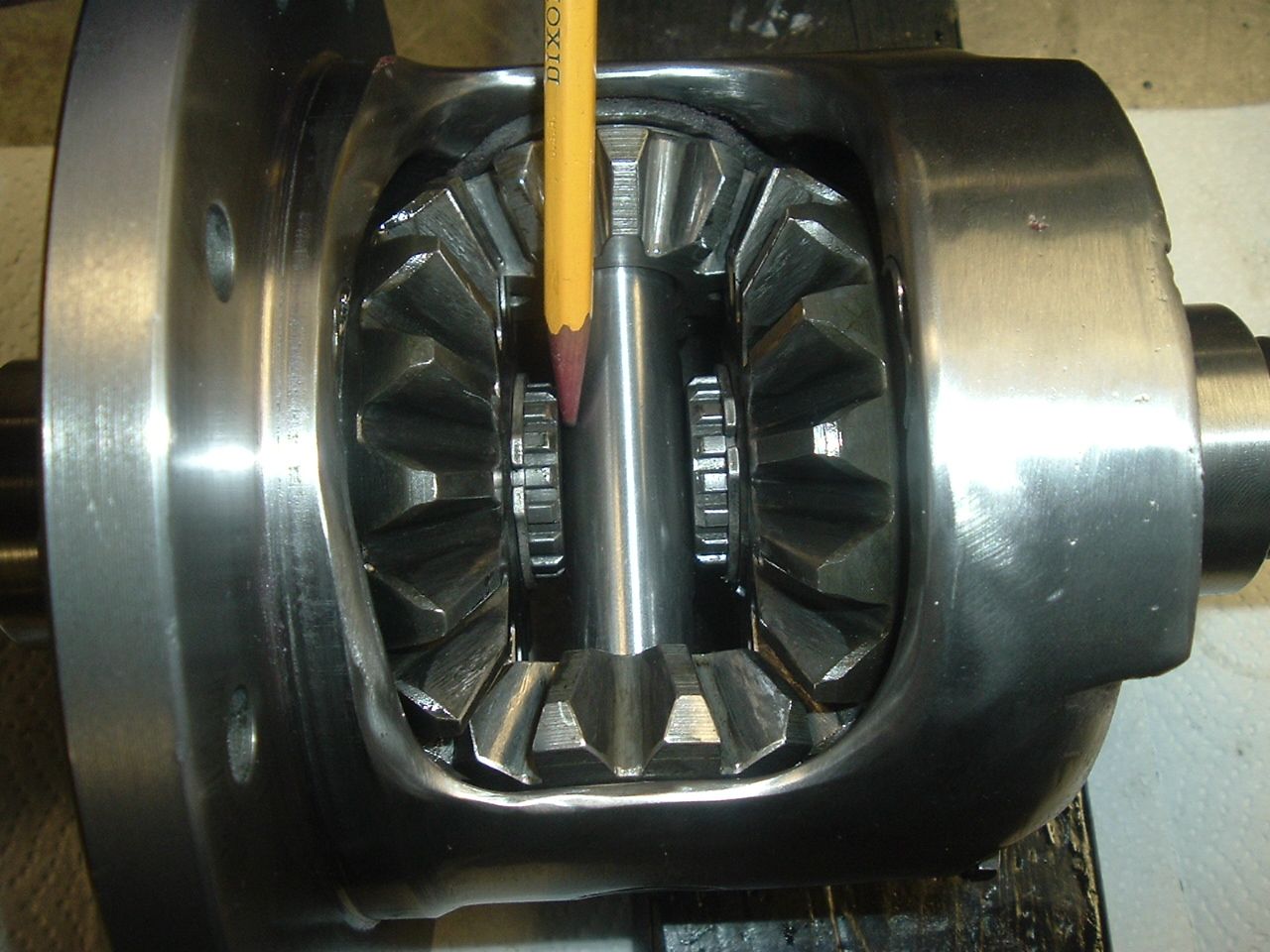

Here are some pictures as well.

Polished & tuned with original axles in place, the endplay was too tight at this point.

Original yoke I reconditioned and ready to set.

Here you can see after a 0015 kiss cut the face is pretty flat, rebuilt yokes aren't this flat!

Done and ready to install.This one was 005"

One last tip for you guys who have a 63-67 with the narrow housings. I mentioned this for years but the shims in the kits sold do not come with the correct case shims. They come with the stackable shims used in the wider housings, 68-79. I've found all kinds of shims in these older diffs from previous rebuilders, this is the correct type. I grind them to size for setup and preload. Be sure you know what type you have before you tear it apart.

Good luck!

If you plan on rebuilding or sending out your diff, take the time to check the yokes(axles) especially if you have a 63-73 that is original. I check everyone I get in but you may find some places figure them in as part of the job. With a 74-79 it is very possible they're worn, they weren't anywhere as good as the 63-73-74's were. Most of the 74-79's had soft faces that wore away and caused some issues. If let go too long they will wear down and grind into the carrier and if it hits the seal then you could lose the carrier all together.

I just finished up a '66 BB diff for a fellow NCRS member and although someone was in this diff before the axles were original. Not only original but the best I've ever seen, better then the current New or rebuilt in fact.

As with most diff's this one had axle endplay, about 050-060". A lot of guys assume the axles are the cause and many times they are, but you really do have to check them and see. When I removed the axles and checked them they were in fact longer then any I've had in, new,rebuilt or original. I don't know the exact spec, if there is one, for the distance from the face to the snap ring- I always look for .180-.187. I had a discussion with someone recently who told me it was supposed to be .170-.175 which is shorter then I like to use. Joe L, John H if you know of this spec please let me know.

With this set of yokes they were dead on .200" and not the cause of the endplay. The stock posi was the cause and typically sloppy, as are the new in the box ones today. I did some machining and fitting and now these yokes are good to reuse & for a long time I might add. I set the endplay to 005-008".

So check yours before you ship it, it could save you $200+ alone. If the endplay is excessive check it when you get it back, if done correct it will be in the 005-008 range- regardless of original,rebuilt,or "new".

Here are some pictures as well.

Polished & tuned with original axles in place, the endplay was too tight at this point.

Original yoke I reconditioned and ready to set.

Here you can see after a 0015 kiss cut the face is pretty flat, rebuilt yokes aren't this flat!

Done and ready to install.This one was 005"

One last tip for you guys who have a 63-67 with the narrow housings. I mentioned this for years but the shims in the kits sold do not come with the correct case shims. They come with the stackable shims used in the wider housings, 68-79. I've found all kinds of shims in these older diffs from previous rebuilders, this is the correct type. I grind them to size for setup and preload. Be sure you know what type you have before you tear it apart.

Good luck!

. Based on all this, do you think it's worth fooling with the clutches?

. Based on all this, do you think it's worth fooling with the clutches?

Comment