Hello all,

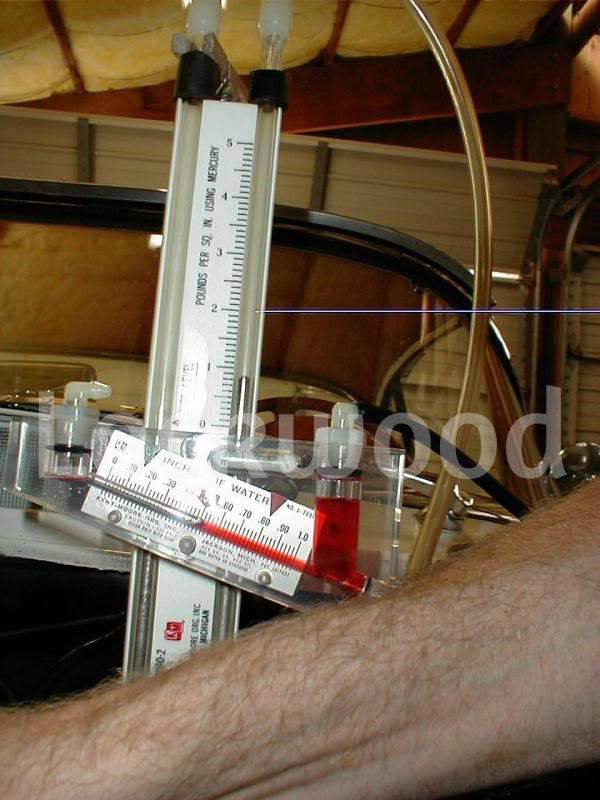

First time using a manometer. My manual says to set 1" HG displacement at .5" water vacuum to set the econ stop. Is that 1.0" HG read directly off of the scale or is it split .5 on the down side and .5 on the up side to equal 1"? I have some conflicting info in my tuning literature.

The Kent-Moore manual says "total displacement of manometer must be read therein from low point on one side of tube to high point on opposite side of tube." The 63 shop manual makes no mention of this.

Thanks for setting me straight. It is a Kent Moore J7090 unit.

Joe

First time using a manometer. My manual says to set 1" HG displacement at .5" water vacuum to set the econ stop. Is that 1.0" HG read directly off of the scale or is it split .5 on the down side and .5 on the up side to equal 1"? I have some conflicting info in my tuning literature.

The Kent-Moore manual says "total displacement of manometer must be read therein from low point on one side of tube to high point on opposite side of tube." The 63 shop manual makes no mention of this.

Thanks for setting me straight. It is a Kent Moore J7090 unit.

Joe

Comment