Frustrating morning at the alignment shop with the 62. Caster spec is 2 degrees +\- 1/2 degree. Best the tech could get was 1/2 degree on the passenger's side and negative .3 degrees on the driver's side. Any thoughts or ideas are appreciated.

C1 Alignment

Collapse

X

-

Re: C1 Alignment

Yes - find a shop with an older machine (and an older operator); even then if any of that center-link/king-pin front end is boogered up a compromise may be the best you can get...Attached Files- Top

Comment

-

Re: C1 Alignment

My experiences have taught me why this may be happening......

When the upper outer and lower outer pins/pivot bolts/bushings( "trunnions" as a old timer taught me years ago ) are installed it the control arms, it is important to center them in the center of the opening in the control arms. If there is offset in one direction on one arm, and if the opposite arm's end is offset in the other direction, this can accumulate and yield a error in caster adjustment capability.

Take a close look at each outer upper and lower bushing. If they are off center, this could potentially cause a problem of this nature.

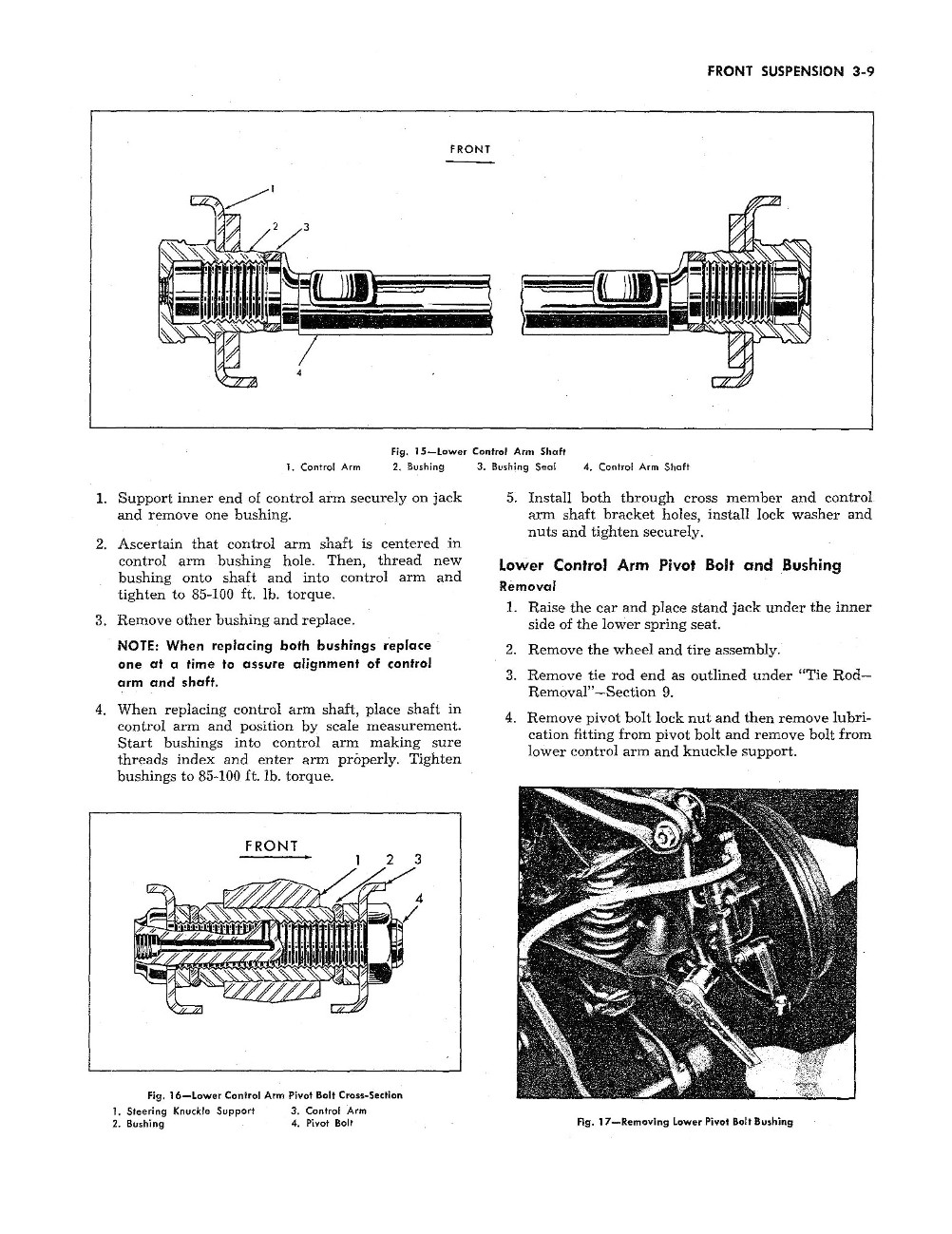

As can be seen in the ST-12 CSM below(fig 16), the center of the bushing with respect to the lower outer control arm opening can be offset if not installed with care.

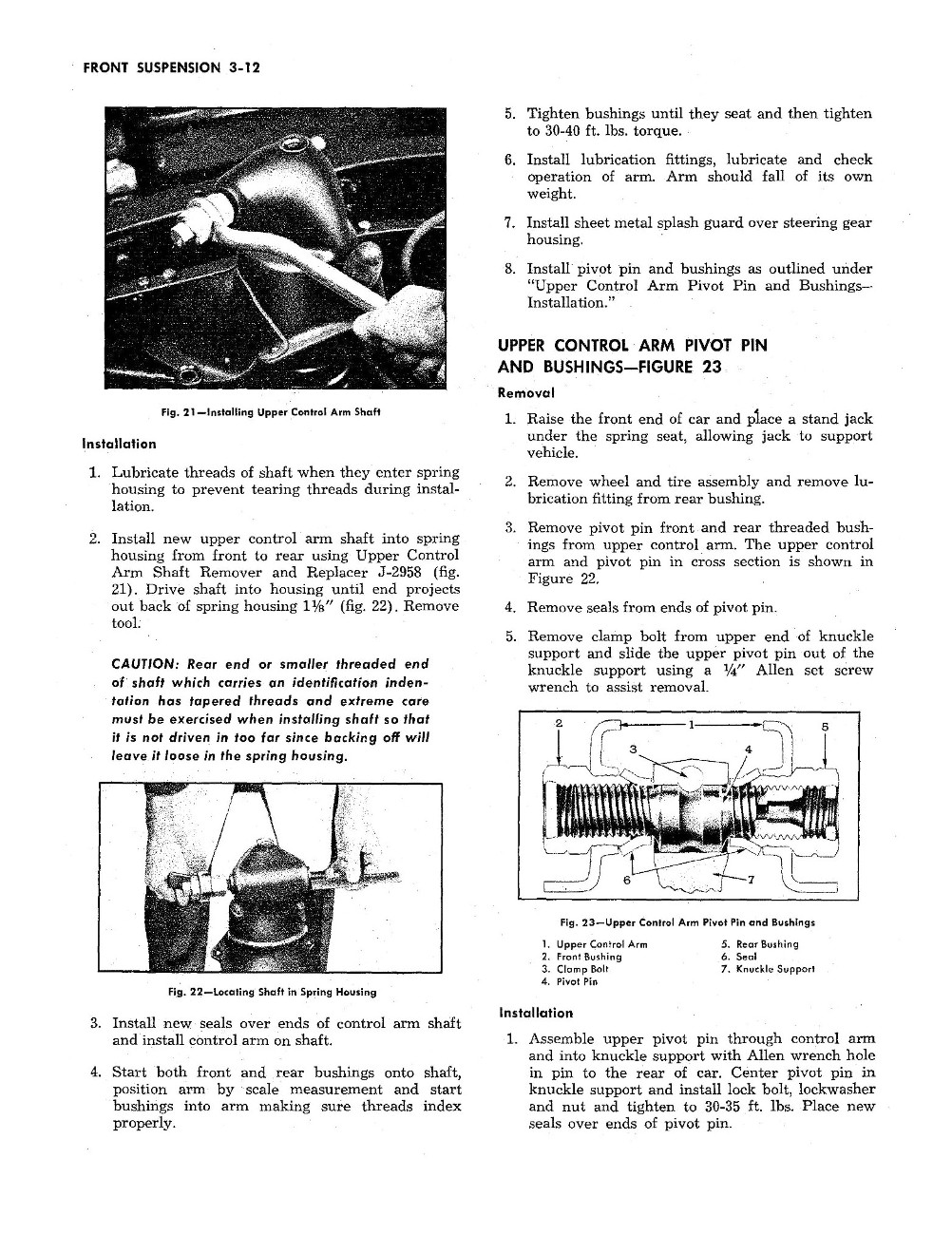

The same is true for the upper as seen in Fig 23....

If there is obvious offset in the bushings with respect to the arm openings, it may be necessary to disassemble the suspension to an appropriate level and re-center the bushings to correct the errors.

Rich- Top

Comment

-

- Top

Comment

-

Re: C1 Alignment

Between the cross member and frame .The bolts that hold the cross member to the frame go though them.Here is the link to Corvette Central.http://www.parts123.com/corvettecent...50e&ukey=47316- Top

Comment

-

Re: C1 Alignment

Some of you may have a hard time believing this........but I saw it with my own eyes.....Years ago I bought a '60 with a very bad case of negative camber (the top of the tires were much closer together than the bottom). I took it to the only place in town with a "Bear Alignment" sign out front with an "old timer" in charge of the shop. He confirmed that the pivot pins and their eccentrics were indeed out of range. They simply could not be rotated further to get anywhere near the desired positive camber. "No problem" he remarked, as he actually chained down both sides of the front end of my car and placed a large hydraulic jack under the center of the crossmember. At which point he and his loyal assistant applied heat (from two acetylene torches) to the upper ends of both knuckle supports. After they began to glow cherry red hot, he then began to apply upward vertical force via the hydraulic jack. Using his "highly trained eye" (no digital electronics here) the knuckle supports began to BEND ever so slightly......to the point where the pivot pins were magically returned to the center of their range. He smiled and said, "Yep....must have been some kids driving the hell out of the car and jumping over some railroad tracks!"

He finished the alignment and I happily drove off with what I came for.....a slightly positive camber!- Top

Comment

Comment